The CRP is a special purpose facility that is capable of recycling spent catalysts and regenerating used catalysts generated by refineries, petrochemical, oleo chemical, pharmaceutical and chemical companies. The Thermal Oxidation Process System (TOPS) technology adopted at QESB offers substantial cost saving benefits to clients. Furthermore, it eliminates landfilling of the spent catalysts, providing a closed-loop system (wherein we minimize wastage through recycling and recovery) as well as providing a more environmental friendly solution for those scheduled wastes.

Utilizing the ‘Thermal Oxidation Process System’ (TOPS) enables the elimination of hazardous contaminants from the spent catalysts. The treated catalyst will then be sent to reputable refiners for the PGM recovery in the form of usable metals such as platinum, palladium, rhodium and silver. Currently, QESB has business and technical partnerships with HERAUES Precious Metal of Germany, Johnson Matthey of United Kingdom and SABIN Metal West Corporation of United States. These refiners are members of the London Platinum and Palladium Market’s (LPPM) Good List and have track records spanning hundreds of years in the PGM refining and trading.

SCREENING PROCESS

Initially, when the spent catalyst enters the CRP, it shall undergo the screening process. The first stage in screening process is to separate between catalysts and non-catalysts. Then, the spent catalyst shall undergo second stage process, where the spent catalyst is separated based on its physical forms; pellets, dust, sweep and broken catalyst.

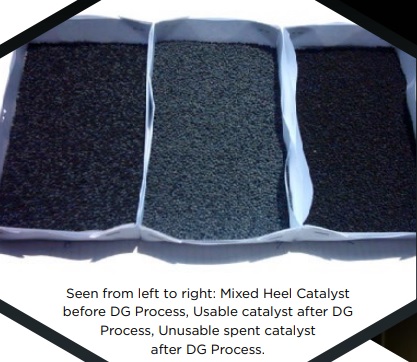

DENSITY GRADING

This value-added service is part of the screening process for separation of used catalyst with subtle physical differences. Density Grading Process separates catalyst particles of similar size based on individual particle density.

TREATMENT

QESB currently use the TOPS technology to treat spent catalyst as it is able to minimize physical impact during the process resulting in higher PGM yield. This process eliminates and reduces contaminants without altering the chemical composition of the spent catalyst.